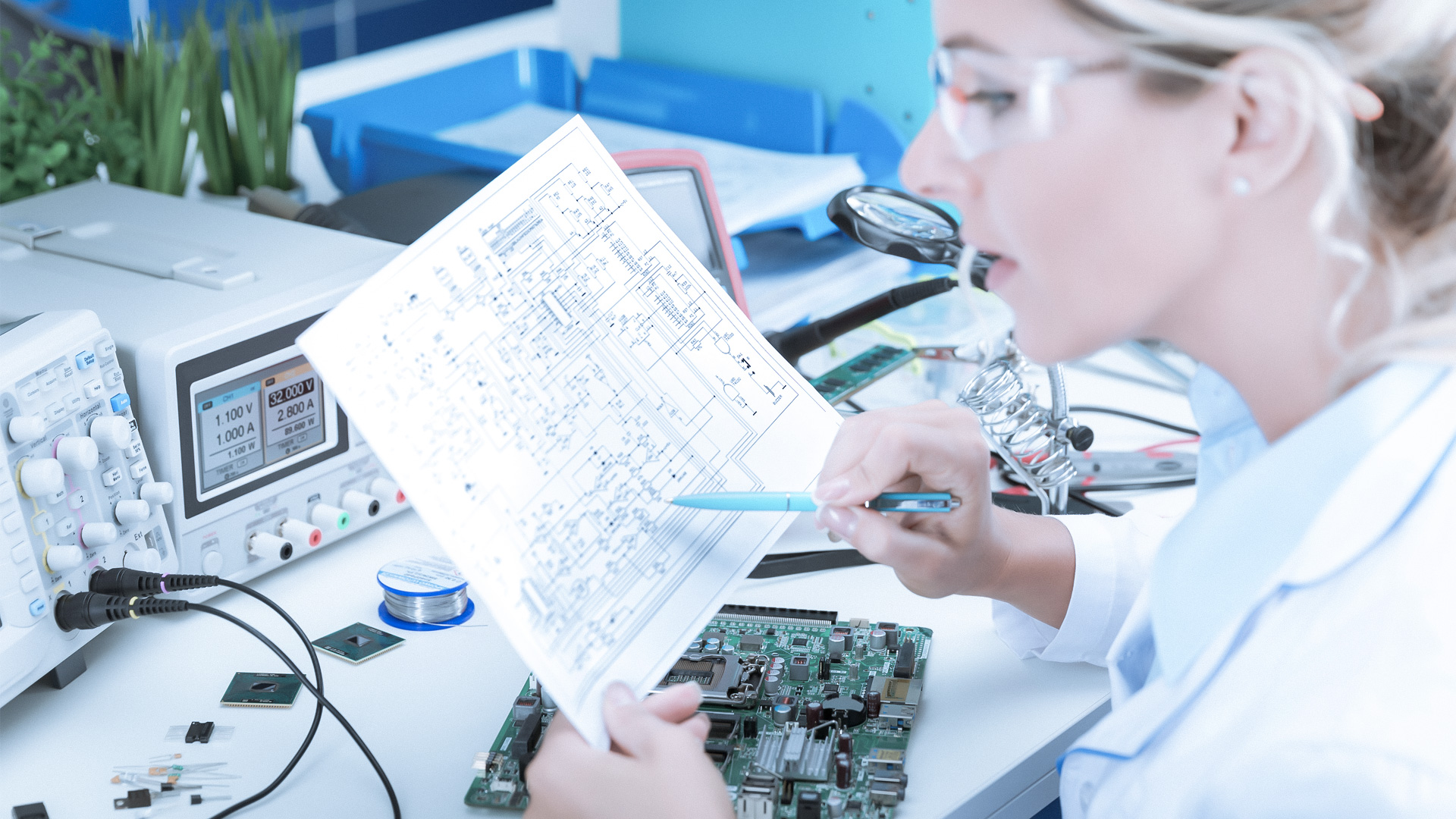

PCB Testing & Inspection Service

PCB Testing & Inspection Service refers to the process of evaluating and verifying the quality, functionality, and reliability of printed circuit boards (PCBs). It involves conducting various tests and inspections to ensure that the assembled PCBs meet the required specifications, industry standards, and customer expectations.

PCB testing and inspection services typically include the following aspects:

Visual Inspection

Conduct a visual examination of the PCBs to identify any visible defects, such as soldering issues, component misalignment, solder bridges, or physical damage. This inspection is often performed manually or using automated optical inspection (AOI) systems.

Optical Inspection

Utilize X-ray machines to inspect the internal structure of the PCB, particularly for components with hidden solder joints, such as Ball Grid Array (BGA) packages. X-ray inspection helps detect issues such as insufficient soldering, voids, or shorts.

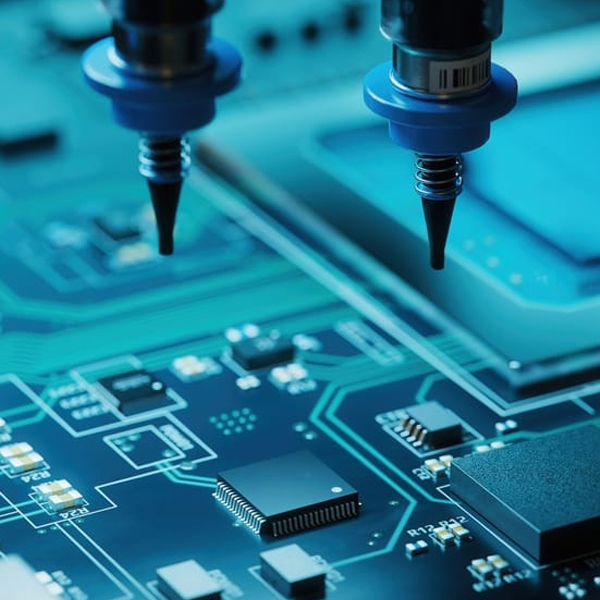

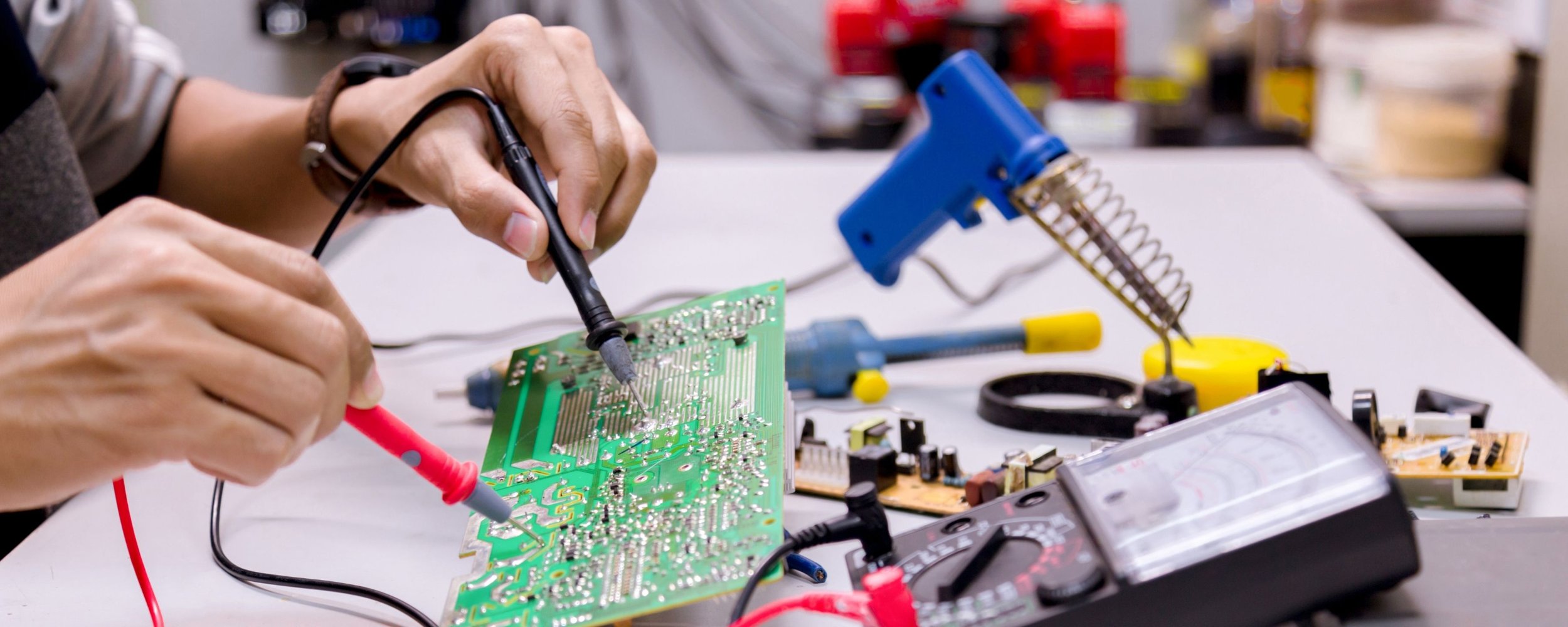

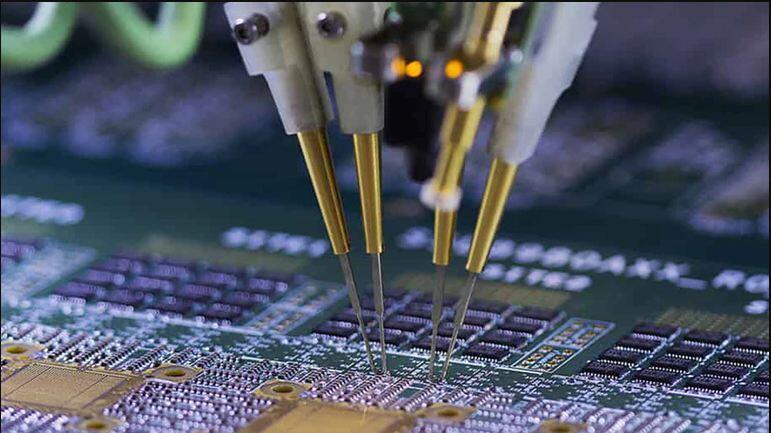

In-Circuit Testing (ICT)

Perform electrical testing of individual components and circuitry on the PCB using specialized ICT equipment. This testing method checks for correct component values, continuity, shorts, open circuits, and other electrical characteristics.

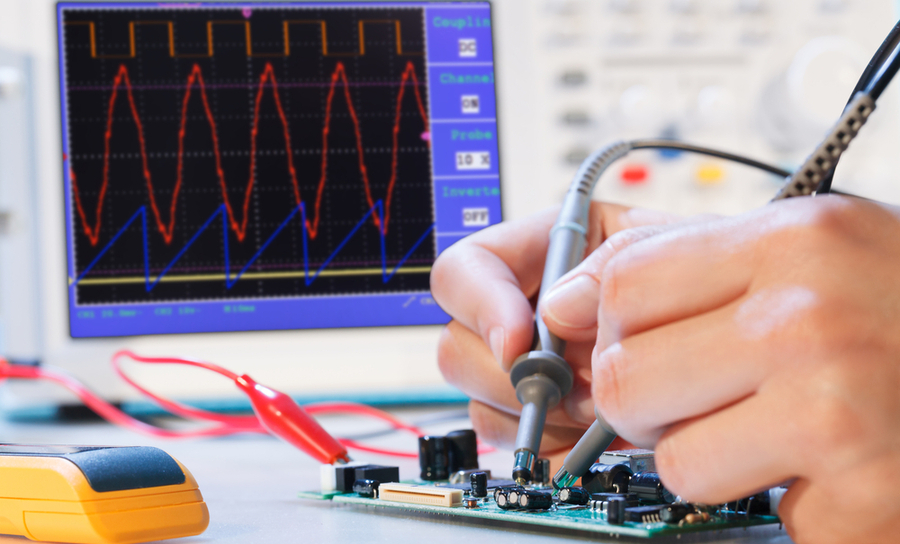

Functional Testing

Evaluate the overall functionality of the PCB by subjecting it to real-world operating conditions or specific test scenarios. Functional testing ensures that the PCB performs its intended functions correctly and reliably.

Boundary Scan Testing

Employ boundary scan testing, which utilizes standardized JTAG (Joint Test Action Group) interfaces, to test the interconnections and functionality of digital components on the PCB. Boundary scan testing helps identify faults such as open circuits, shorts, or incorrect signal paths.

Environmental Testing

Subject the PCBs to environmental conditions such as temperature variations, humidity, vibration, or thermal cycling to evaluate their performance under different operating conditions. Environmental testing helps assess the PCB’s reliability, durability, and resistance to environmental stress.

RoHS Compliance Testing

Verify compliance with RoHS (Restriction of Hazardous Substances) directives by testing for the presence of restricted substances, such as lead, mercury, cadmium, and certain flame retardants, within the PCB and its components.

Documentation and Reporting

Provide detailed reports and documentation summarizing the test results, inspection findings, and any identified issues or recommendations for improvement. These reports serve as quality assurance records and assist in troubleshooting and continuous improvement efforts.

PCB testing and inspection services are essential to ensure the quality and reliability of the assembled PCBs. By conducting rigorous testing and inspections, potential defects or issues can be detected and resolved early in the production process, leading to improved product quality and customer satisfaction.

Reach out to Epsilon Electronics for your next PCB Testing & Inspection requirements.

Email Us

pcb@epsilonelectronics.in

Call US

+91 98796 26181 / 079-4800-2842

Related Other Services

BOM Sourcing

BOM Sourcing

BOM sourcing service refers to a service that assists in the procurement of Bill of Materials (BOM) components for manufacturing or product assembly.

SMT PCB Assembly

SMT PCB Assembly

SMT (Surface Mount Technology) PCB Assembly is a method of assembling electronic circuits on printed circuit boards (PCBs).

Through Hole Assembly

Through Hole Assembly

Through-hole PCB Assembly is a method of assembling electronic circuits on printed circuit boards (PCBs) using through-hole components.

Turn Key PCB Assembly

Turn Key PCB Assembly

Turnkey PCB Assembly service refers to a comprehensive service provided by a manufacturing company or assembly house where they handle...