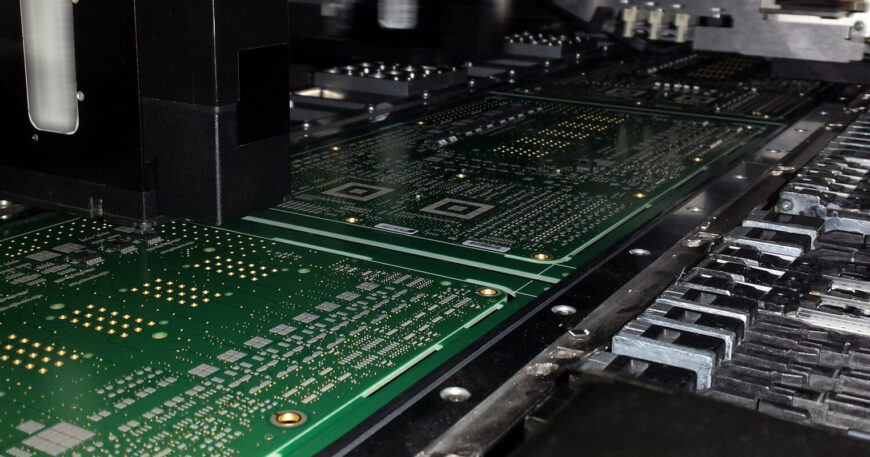

The choice of PCB substrate type for fabrication depends on the specific requirements of your electronic circuit and the intended application. Here are some considerations to help you determine the suitable PCB substrate type for fabrication:

FR-4 (Flame Retardant 4)

FR-4 is the most common and widely used substrate material for general-purpose PCB fabrication. It provides good electrical insulation, mechanical strength, and is cost-effective. If your application doesn’t have specific high-frequency or high-temperature requirements, FR-4 is a solid choice.

High-Frequency Materials

If your application involves high-frequency signals (RF or microwave), you might consider specialized high-frequency materials like those from the Rogers Corporation (e.g., RO4000 series). These materials offer low dielectric loss and are designed to maintain stable electrical properties at higher frequencies.Flex PCBs with Polyimide

For flexible PCBs or applications where the board needs to be bent or twisted, polyimide (PI) substrates are commonly used. Polyimide is flexible and can withstand repeated flexing without compromising its integrity.Metal Core PCBs (MCPCBs)

If your design involves high-power components or LEDs that generate significant heat, metal core PCBs with aluminum or copper cores are suitable. These materials provide better thermal conductivity, aiding in heat dissipation.Ceramic Substrates

In applications where high thermal conductivity and excellent electrical insulation are crucial, ceramic substrates like alumina or aluminum nitride may be considered. These are often used in high-power and high-frequency applications.Specialized Materials for Harsh Environments

If your electronic circuit will be exposed to harsh environmental conditions (extreme temperatures, chemicals, moisture), you might need specialized substrate materials designed to withstand such conditions.● Layer Count: The number of layers in your PCB can affect the choice of substrate. FR-4 is suitable for multilayer boards, but certain high-frequency materials may have limitations.

● Cost: Different materials come with varying costs. FR-4 is generally cost-effective, while specialized materials may be more expensive.

●Availability: Ensure that the chosen substrate material is readily available from your chosen PCB fabrication service.

Reach out to Epsilon Electronics for PCB Design, PCB Fabrication, BOM Procurement, Hardware Manufacturing, PCB Assembly. Our expert team can help you to launch your product on time with all quality aspect consideration at every stage.

Contact Info:

Call Us: +91 9879 6261 81

Email: pcb@epsilonelectronics.in

Web: www.mfg.epsilonelectronics.in